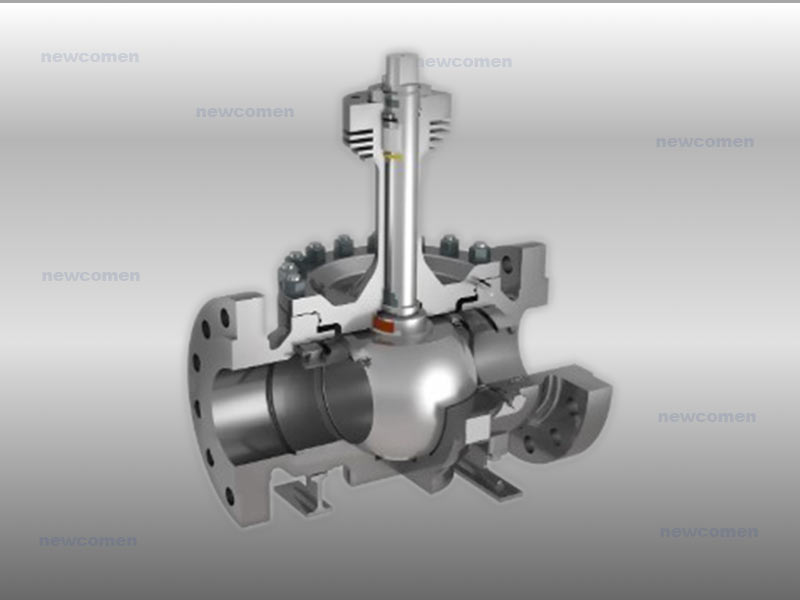

Description

Material (Forged Valve):

- Body, Bonnet, and Ball: Forged Carbon Steel, Low Temperature Carbon Steel, or Stainless Steel (e.g., 316L, 316LN)

- Stem: 17-4PH Stainless Steel or other low-temperature compatible materials

- Seat: PTFE or other low-temperature compatible soft seat material

- Stem Seal: PTFE or other low-temperature compatible packing

Material (Casted Valve)

- Body, Bonnet, and Ball: Cast Carbon Steel, Low Temperature Carbon Steel, or Cast Stainless Steel (e.g., CF8M, CF8)

- Stem: 17-4PH Stainless Steel or other low-temperature compatible materials

- Seat: PTFE or other low-temperature compatible soft seat material

- Stem Seal: PTFE or other low-temperature compatible packing

Performance:

- Temperature Range: -196°C to 120°C (or lower, depending on specific design)

- Pressure Rating: Class 150, 300, 600, 900, or 1500 (or higher, depending on specific design)

- Leakage Class: Zero leakage or low leakage, depending on the specific application

- Cycle Life: High cycle life, suitable for frequent operation

Considerations:

- Low-Temperature Lubrication: Special low-temperature lubricants may be required for valve operation

- Thermal Shock Resistance: The valve is designed to resist thermal shock

- Corrosion Resistance: The valve is resistant to corrosion from the cryogenic fluid and any impurities it may contain.

- Cryogenic Fluid Compatibility: The valve materials and lubricants must be compatible with the specific cryogenic fluid being used.

Download Datasheet (PDF)

Reviews

There are no reviews yet.