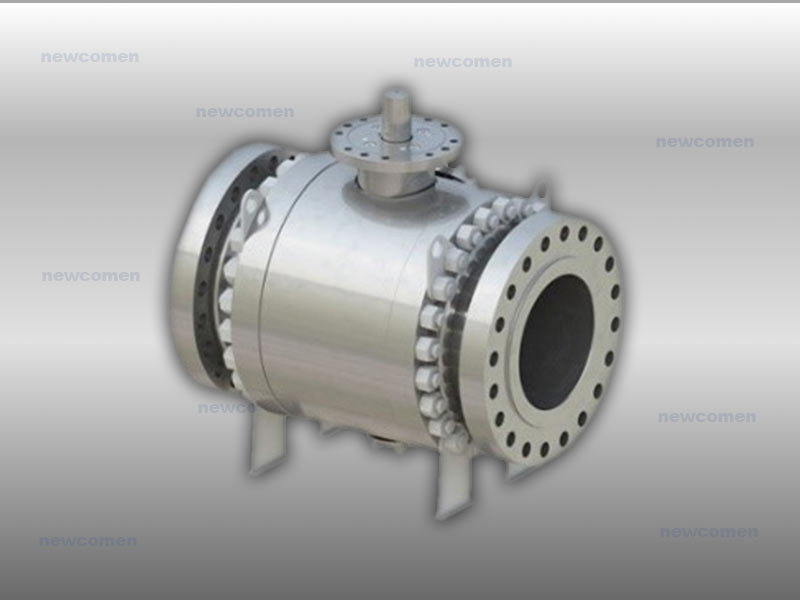

Description

Trunnion ball valves are a type of valve that uses a spherical ball to control the flow of Fluid. Unlike floating ball valves, trunnion ball valves have the ball mounted on trunnions, which are bearing points that support the weight of the ball. This design allows for larger valve sizes and higher pressure ratings.

Advantages of Trunnion Ball Valves:

- High Pressure and Temperature Ratings: Due to the trunnion design, these valves can handle higher pressure and temperature ratings than floating ball valves.

- Reduced Friction and Wear: The trunnion bearings minimize friction and wear on the ball and seat rings, leading to longer service life.

- Improved Sealing Performance: The trunnion design ensures precise alignment of the ball and seat rings, leading to better sealing performance.

- Reliable Operation: The robust construction and precise engineering of trunnion ball valves contribute to their reliable operation.

Forged Trunnion Ball Valve Bodies:

- Carbon Steel:

- ASTM A105: A common choice for general-purpose applications.

- Alloy Steel:

- ASTM A182 F1: Suitable for higher temperature and pressure applications.

- ASTM A182 F9: Offers good resistance to corrosion and oxidation.

- ASTM A182 F11: Provides excellent resistance to high temperatures and pressures.

- Stainless Steel:

- ASTM A182 F304/304L: Offers good corrosion resistance and is suitable for a wide range of applications.

- ASTM A182 F316/316L: Provides excellent resistance to corrosion, particularly in chloride-containing environments.

- Duplex Stainless Steel: (e.g., ASTM A182 F51, F53) Offers excellent corrosion resistance and high strength.

Cast Trunnion Ball Valve Bodies:

- Cast Steel:

- ASTM A216 WCB: A common choice for general-purpose applications.

- ASTM A216 WCC: Suitable for higher temperature service.

- Alloy Steel:

- ASTM A217 WC9: A common choice for high-temperature service.

- ASTM A217 WC6: Offers good strength and toughness at elevated temperatures.

Ball Materials for Floating Ball Valves

- Stainless Steel:

- 304/304L: Offers good corrosion resistance and is suitable for a wide range of applications.

- 316/316L: Provides excellent resistance to chloride-containing environments.

- Carbon Steel:

- Used in less demanding applications where corrosion resistance is not a primary concern.

- Alloy Steels:

- Used in high-temperature or corrosive service applications. Specific alloys will depend on the specific requirements.

- Special Alloys:

- Materials like Stellite or Monel may be used in highly corrosive or abrasive service conditions due to their exceptional wear and corrosion resistance.

Temperature Rating

- Carbon Steel: Typically, up to 425°C (800°F)

- Stainless Steel (316): Up to 650 °C (1200°F)

- High-Performance Alloys: Can handle even higher temperatures, often exceeding 816 °C (1500 °F)

Packing Material

- Graphite: Offers excellent sealing performance and resistance to high temperatures.

- PTFE: Provides low friction and good chemical resistance.

- Elastomers: Such as NBR, Viton, and EPDM, offer good sealing performance and flexibility

- Ceramic: Highly resistant to high temperatures and corrosive environments

- Metallic Packings: Suitable for high-temperature and high-pressure applications

Download Datasheet (PDF)

Reviews

There are no reviews yet.